Rubbing Color fastness Tester solution|color fastness test : import Test procedure. Rating. Report. How to improve the color fastness of fabrics to . WEBCase No. 7906277 - the Party Thieves. Kimmy and Lulu are stepsisters with a lot of money and a love for partying. They attempt to shoplift from the store to get party supplies, but .

{plog:ftitle_list}

WEBComendo cu apertado da gostosa de quatro 65 sec. 65 sec Proib1D - 720p. Comi a priminha novinha de quatro quando ninguém estava em casa 6 min. 6 min Casalsecretox - 22.8k Views - 1080p. fodendo novinha magrinha de quatro 2 min. 2 min Shindoxdd - 720p. comendo o rabo da novinha safada bem gostoso 7 min.

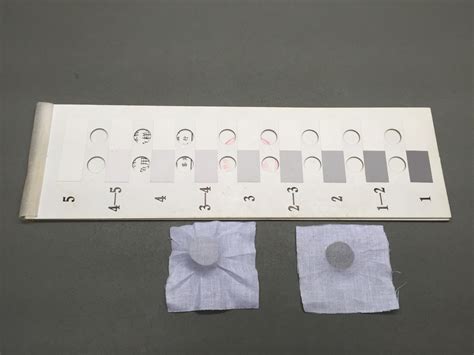

Color fastness to rubbing. Rubbing fastness refers to the degree of color fading of dyed fabrics after rubbing. This can either be from dry rubbing or wet rubbing. The rubbing fastness is determined from the degree of a prespecified white cloth’s staining, and it is graded .Testing Principle. The wash fastness test involves affixing textile samples to one .

Test procedure. Rating. Report. How to improve the color fastness of fabrics to .

This test is essential for ensuring that textiles do not bleed or stain other materials when subjected to rubbing, which is particularly important for items like apparel, upholstery, . Color fastness to rubbing test is designed to determine the degree of color which may be transferred from the surface of a colored fabric .A test for fastness to rubbing can be performed on dry or wet fabric. The tester needs a small piece of the fabric and a white test cloth. The test cloth is put on the grating and stag using stainless steel wire. The cloth swatches are rubbed .

Rubbing Color Fastness: Place the test specimen on a rubbing fastness tester and rub it a certain number of times with a standard rubbing white cloth under specific pressure. Perform both dry and wet rubbing color fastness .

Testing Principle. The wash fastness test involves affixing textile samples to one or two specified lining fabrics, immersing them in a soapy solution, subjecting them to mechanical agitation, followed by rinsing and .

Test procedure. Rating. Report. How to improve the color fastness of fabrics to rubbing? Dye performance. Color depth (dye concentration) The influence of floating color. After reading these, we can . Principle: A colored test specimen is rubbed with white crock test cloth under controlled conditions. Color transferred to the white test cloth is assessed by a comparison with the Gray Scale for Staining or the Chromatic .

This Rubbing Colour Fastness Tester is used for assess colored materials friction damage and surface color transfer. It is suitable test the upper materials, such as leather, plastics and fabric etc. Standards: BS EN 13516 Method B, . Color fastness to perspiration test is used to determine the resistance of the color of textile of all kinds and in all . Before knowing about the Color Fastness to perspiration you must have to know about Color .AB-301 Color Fastness Rubbing Tester. Purpose. The machine is the most standard type to measure fiber and printed matter for fastness against friction. Number of samples: 6 pcs: Load: 200 , 500gf: Rubbing finger:Veslic Rub Fastness Tester is used to test leather rub color fastness by to-and-for rubbing with a wool felt. And it is suitable to test all kinds of leathers. Veslic Rub Fastness test standard includes: ISO 11640, DIN 4843 and etc.

wet rubbing colour fastness test

The color fastness test of textile materials is the most encountered and the most headache in the textile industry. In addition to the color fastness to perspiration test, there are common Color Fastness to crocking test, color fastness to rubbing, color fastness to washing, color fastness to light, and so on. Try to grasp the test from the .

rubbing fastness test

Application: This Rubbing Colour Fastness Tester is used for assess colored materials friction damage and surface color transfer. It is suitable test the upper materials, such as leather, plastics and fabric etc. Standards: BS EN 13516 Method B, SATRA PM8,QB/T 1619-2018 annex B, ISO 17700 Method B You may also like: How to Determine Color Fastness to Wash. In my personal experience, in case of fastness test, colour fastness to washing is the first and most important requirements of buyers. There are a number of ISO test for colour fastness to washing. List of ISO Test for Colour Fastness to Washing: ISO test no-1; ISO test no-2; ISO test .Iultcs Rubbing Color Fastness Tester meet ISO / 105, ASTM/D2054, 亚洲航空技术中心 / 8, JIS/L0849 ISO - 11640, 赛特拉 PM173, QB/T2537标准, ETC. 86-769-83078748 . 86-13751328225 [email protected] What is a crock meter? How does a crock meter work? From the test apparatus, there are three types used to do color fastness to rubbing test: parallel reciprocating type (commonly used in Europe, America, and China), over-bridge type (commonly used in Japan), and rotary rubbing type.These rubbing fastness testers are usually called crock meters, .

The operation of the Rubbing Fastness Tester includes subjecting a sample of the material that is to be tested to rubbing or friction against a standardized fabric under monitored and controlled conditions. The rubbing action is achieved by using a reciprocating or .

The "Color fastness to rubbing test" evaluates "color transfer (staining) to other layered shirts" due to the effect of rubbing. . The JIS L 0860 A-1 method uses a test solution that is a mixture of perchloroethylene, surfactant, and water. 20 stainless steel balls are put in the testing solution and washed at 30℃ for 30 minutes.The wet rubbing cloth is placed on to the grating and stag with stainless steel wire and run ten times manually then assesses the attaining on to the rubbing cloth and the rubbing fastness of the sample cloth is accessed.At present, the textile instrument industry has different types of wet and dry rubbing color fastness test instruments, and .

Colorfastness to rubbing is a test method through color loss after rubbing colored fabrics. There are two types of friction: dry friction and wet friction. The assessment of fabric color fastness by this method is derived from a comparison of white fabric with a gray card rating. The test results in this method are generally divided into 5 .

The GT-D04 Electronic Rubbing Fastness Tester and GT-D05 Manual Rubbing Fastness Tester are essential tools for accurate color fastness testing. This article provides an in-depth analysis of these testers, detailing their features, application scenarios, and . Color Fastness to Rubbing Test Procedure: The test specimen is placed on the base of the Crockmeter and a square of white test cloth is rubbed on the colored specimen by means of the Crockmeter finger (dry test cloth for dry crocking; test cloth wet out in distilled water for wet test; wet pickup 65+/- 5%). The sample is rubbed twenty times . For apparel, the most common “challenges” are exposure to light, loss of dye during laundering, rub fastness, which measures whether color is lost from the fabric surface after mechanical rubbing, perspiration fastness, .

As required by different color fastness test menthods, the color fastness testing equipment can be different. color fastness to perspiration test method: Perspiration tester; colour fastness to crocking test: Crockmeter; color . In order to fulfill these criteria, several types of test method have been proposed for assessing textile color fastness. Different Types of Colour Fastness Test: Colour fastness to washing; Colour fastness to laundering; .

where to get bottled water tested

The color change of the fabric is measured using the Grey Scale for Color Change, as in other AATCC color fastness test standards. Importers will typically accept a grade 4 rating for this test. 4. Color fastness to perspiration test. The color fastness to perspiration test determines the resistance of textile colors to human perspiration.

which bottled water brands test for ofas

22 years focused on physical lab testing machines and provide total testing solution according customer requirement. . the international standard for testing color fastness to rubbing mainly includes the International Organization for Standardization Standard ISO 105-X12: 2001 'Textile Color Fastness Test Part X12: Color Fastness to Rubbing1 .Color Fastness to rubbing. When it comes to colorfastness, there are a few different factors to consider: light fastness, wet fastness, and rubbing fastness. . The test involves submerging samples in either water or a dilute acid solution. The color of the sample is observed and recorded. If color shifts to a new shade are noted, the fabric .

Solution www.tec-color.com Crockmeter Rubbing Fastness Tester To determine colour fastness of textile to dry or wet rubbing, fitted with hand crank/counter. . textile to dry or wet rubbing, fitted with hand crank/counter. Provided with a steel specimen holder and 16mm diameter test finger. Weight Dimensions Standards 6 kg 160 x 600 x 215 mm .Understanding the standards and methods for crock testing ensures consistent and reliable results. The crock meter test and rubbing fastness test method follow specific guidelines to maintain uniformity in textile testing. 1. ISO 105-X12: Color Fastness to Rubbing. ISO 105-X12 is a key international standard for testing the color fastness of .

This is a test instrument for determining the resistance of the colour of textiles of all kinds to rubbing off and staining other materials using convex specimen stage (colour fastness to rubbing). Evaluate the degree of staining (color migration) of the cotton rubbing cloth for rubbing test that rubs the sample with a constant downward force.Gakushin Rubbing Colorfastness Tester is mainly used for the evaluation and judgment of the color fastness to rubbing of dyed fiber products; use a dry or wet white cotton cloth to tie the surface of the friction head of the machine, and rub the colored test piece with a certain load and number of times. Evaluate the grade of color fastness to rubbing; it can also be used as a . In this test, the fabric samples are exposed to a xenon arc lamp, rather than natural daylight. A similar test method is also described in AATCC 16.3. Colorfastness to Rubbing. Colorfastness to rubbing tests measure a fabric's ability to resist color transfer from the surface of the textile to another surface through friction.1 200 ± 1 4 test specimen ρ 2 45 ± 1 5 cotton rubbing cloth 6 rubbing finger Figure 1 — Typical diagram of rubbing meter (Gakushin test method) 5.2 Cotton rubbing cloth, in accordance with ISO 105-F09, is at least 50 mm squares. 5.3 Grey scale .

Color Fastness Tester, Crocking Fastness Tester, Rubbing Fastness Tester, Washing Fastness Tester, Light Fastness Tester, Perspiration Fastness Tester, Sublimation Fastness Tester . The test specimen is dipped in alkaline solution a liquor ratio of 50:1 and allowed to remain in the solution at room temperature for 40 minutes. The excess .

fabric fastness to rubbing test

webFundação Cultural Palmares e G20 numa perspectiva Afro-brasileira 27/02/2024. FCP recebe integrantes da Sociedade Recreativa União Operária de Criciúma 21/02/2024. 4° Conferência Nacional de Cultura: O Futuro da Cultura Brasileira em Debate 27/02/2024. Mais notícias. Cenário Cultural.

Rubbing Color fastness Tester solution|color fastness test